CPP Sealant Film for Ultrasonic Sealing

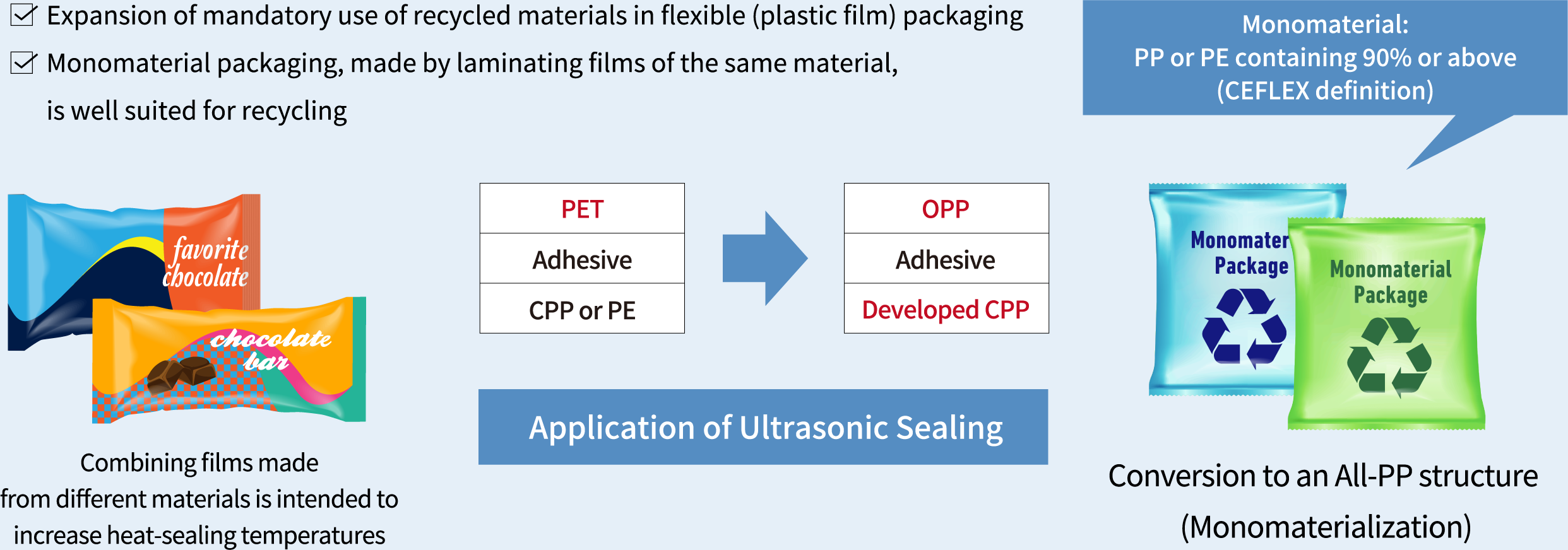

Advancing Monomaterial Packaging as the Industry Standard

CPP Sealant Film Optimized for Ultrasonic Sealing

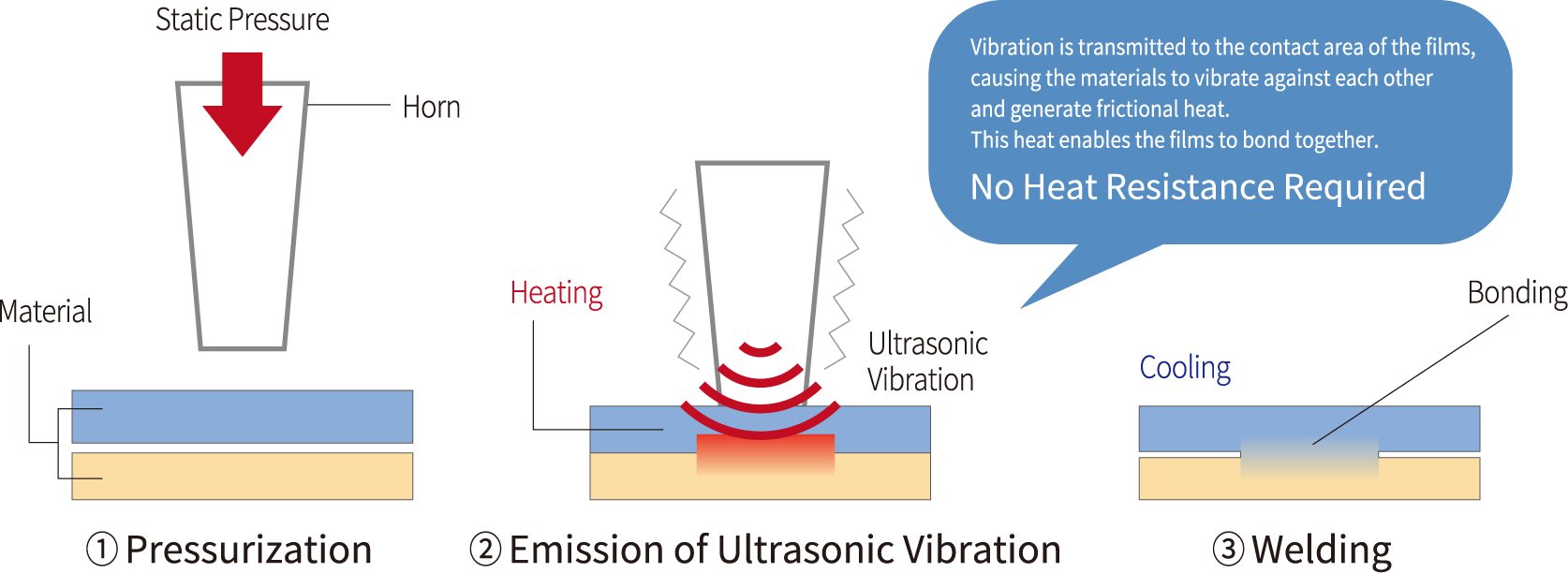

What Is Ultrasonic Sealing?

Ultrasonic sealing is a next-generation sealing technology that welds materials using frictional heat generated by micro-vibrations.

In recent years, it has been gaining attention both domestically and internationally due to its environmental friendliness and its aspect of enhancing productivity.

Mechanism of Ultrasonic Sealing

Instantly seals the packaging materials through frictional heat generated by vibration.

Benefits of Ultrasonic Sealing

Four Key Values of Ultrasonic Sealing

Advantages of DIC’ s CPP Sealant Film (Development Product) for Ultrasonic Sealing

Comparison of DIC’s CPP sealant film and a conventional CPP sealant film with an OPP 20μm / CPP 20μm structure

1

Stable Sealing Performance

Minimal variation in seal strength even at higher packaging speeds

Comparison of seal strength and variation of the end seal section

2

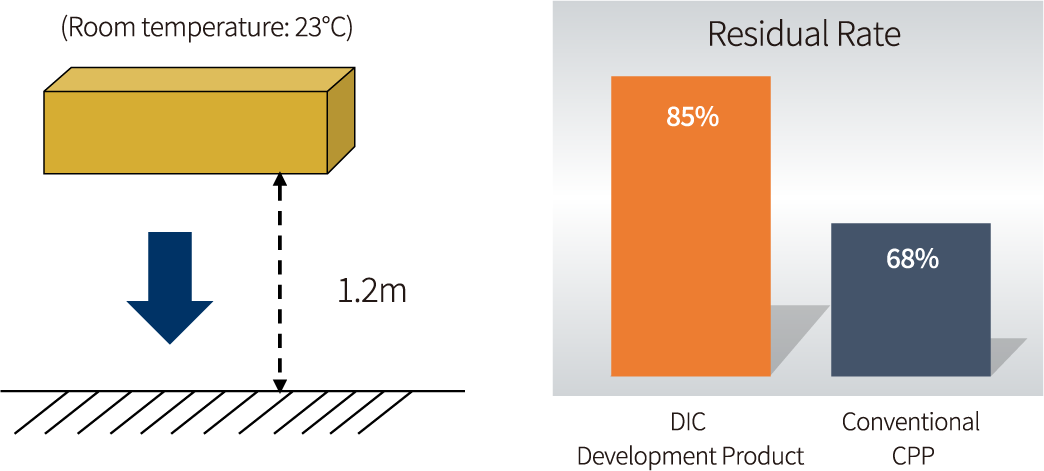

High Resistance to Package Rupture

Higher residual rate compared to conventional CPP

Drop test

Item: Ten corrugated boxes containing individual packages with contents

Test method: Two drops conducted on each face, in total of twelve drops

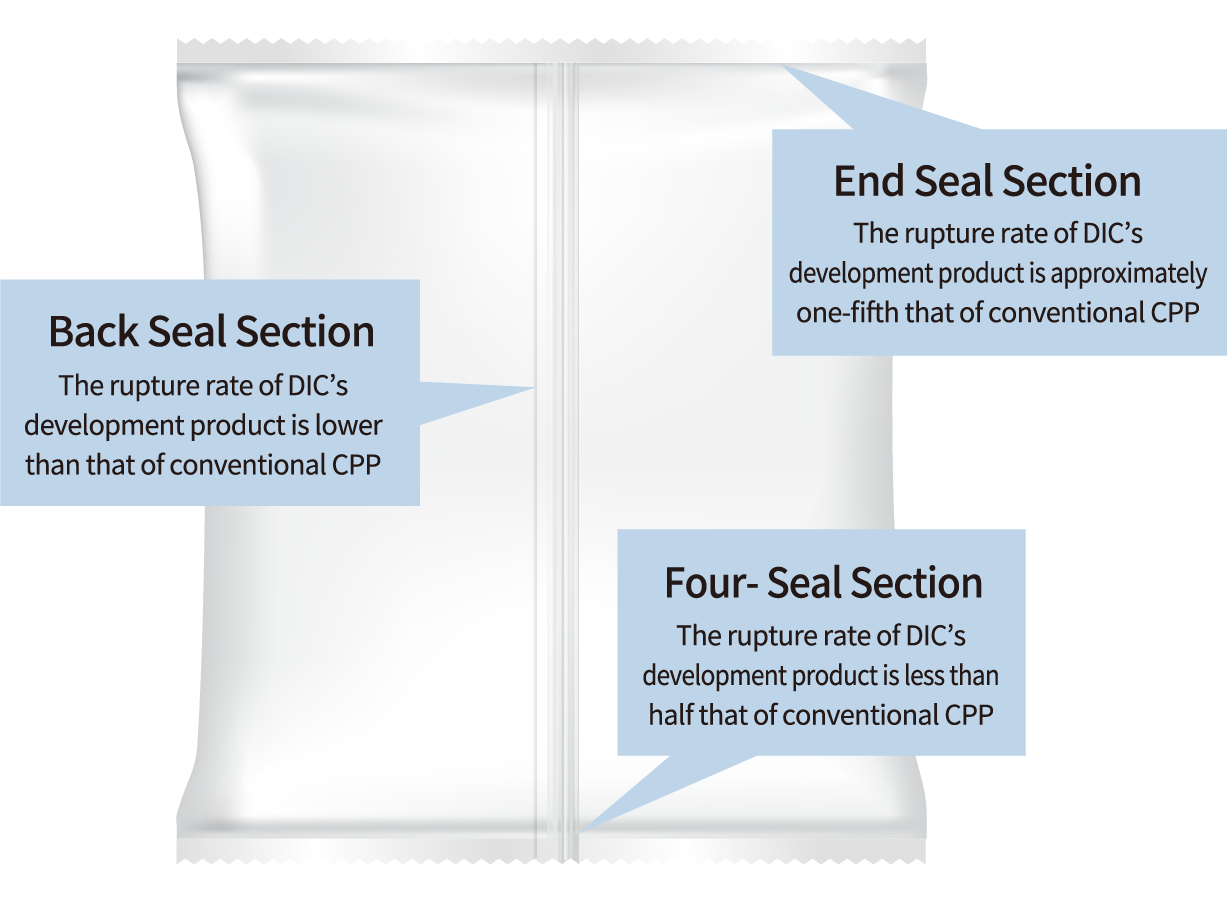

Analysis of Package Rupture Points

DIC’s development product offers superior

ultrasonic sealing performance,

including stronger end seals and enhanced rupture prevention.

【Verification of Sealing Performance of the Development Film】

Packaging tests were performed using actual production machines in collaboration with the packaging machine manufacturer FUJI MACHINERY CO.,LTD.

Monomaterial Packaging Becomes Possible with Ultrasonic Sealing

If you are interested in this product or would like more detailed information, please feel free to contact us.