Creating eco-friendly packaging materials with water-based flexo

About Marine Flex series (water-based flexographic ink)

- Environmentally friendly packaging design

Responding to small lots and high-variety items

Organic solvent-free as much as possible

It is possible to reduce the environmental burden one step further than gravure printing.

Contributing to the design of packaging materials that are friendly to the environment and people.

Enables printing on substrates that were previously difficult to print on

Printing is possible not only on film but also on paper, rayon paper, Japanese paper, non-woven fabric, etc.

Less than 1/10 of the amount of VOC and CO2 generated during printing

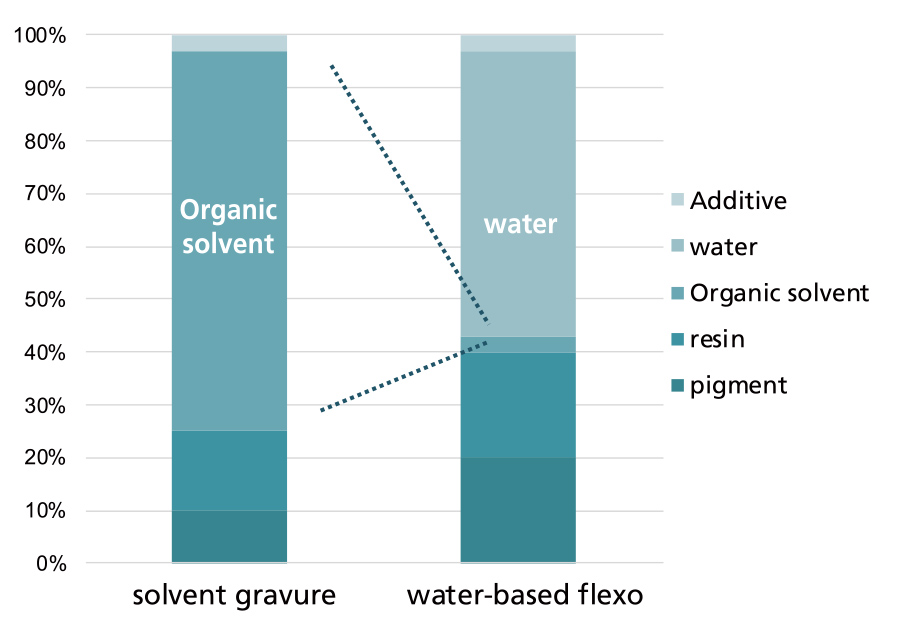

Since the amount of VOC in the ink is small, the amount of VOC and CO2 emitted during printing can be greatly reduced compared to oil-based gravure.

| Oil-based gravure | Water-based gravure | Water-based flexo | |

|---|---|---|---|

| ink ingredients *during printing |

VOC80% | VOC40% | VOC2-5% |

| wet coating amount (g/㎡) |

6 | 4 | 2.5 |

| Amount of VOCs generated (When printing 100,000m) |

480kg | 150kg | 0.6kg |

| Amount of CO2 generated (When printing 100,000m) |

1,037kg | 320kg | 1.25kg |

Eco-friendly packaging with water-based flexo!

[New Product] Marine Flex LM-R

feature

- Significant reduction of VOC and CO2 by water-based.

- Low odor and friendly to the global environment and working environment.

- High-definition printing is possible with high-density settings equivalent to gravure printing.

All you need to know in 60 seconds about Marine Flex series

Video window pops up

No Audio

No Audio

Those who want to see detailed information

Click here for inquiries