Co-extruded multi-layer film can package just by itself!

About co-extruded multi-layer film DIFAREN®

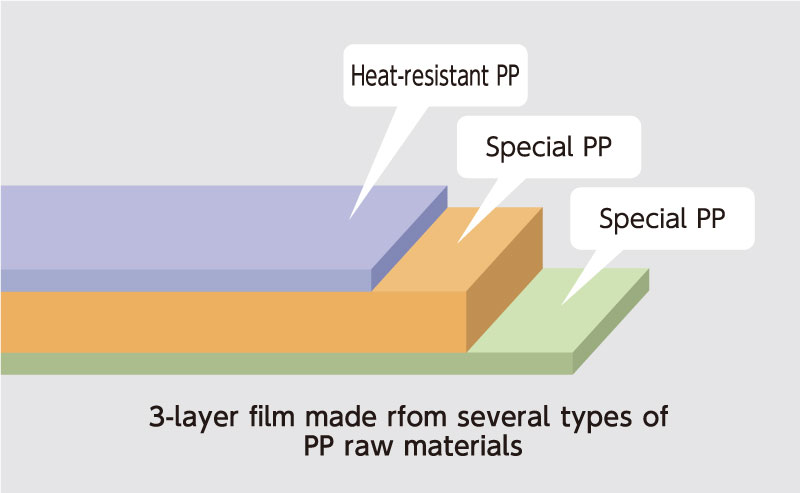

- ・It is a single, multi-layer non-oriented film

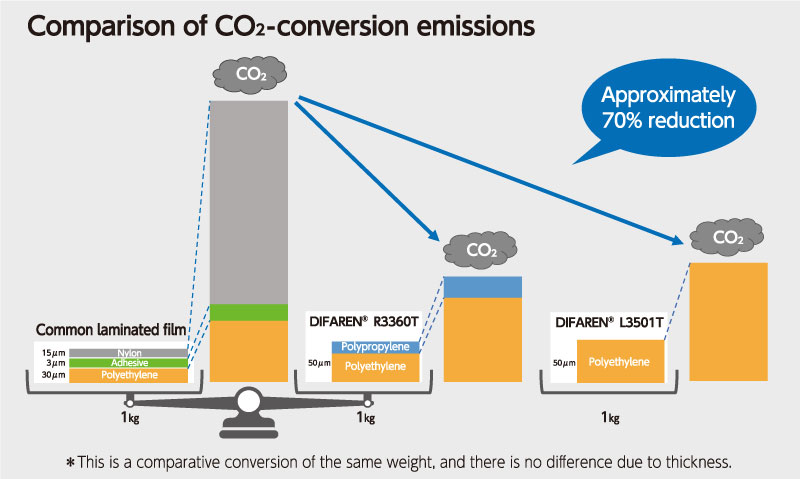

・No lamination required, supporting CO₂ reduction. Mono-material products are also available

Reduction of CO₂ emissions by switching from lamination structure

Cold-resistant grades “R3360T” and “L3501T” can be pillow packaged as a stand-alone product. Despite being a single film, it has a difference in melting point between the front and back surfaces, enabling good suitability for packaging machines. Switching from a laminated structure contributes to reduction of CO₂ emission.

<New product> Film for outer packaging, DIFAREN® P2170T

DIFAREN® P2170T can be set in packaging machines directly be cause it has a good stiffness and suitability for packaging machines. Suggested for switching from laminate structure.

[New Product] Easy-Open Anti-Fog CPP Film: DIFAREN®S1720T

This film for food pillow packaging features anti-fog and easy-open properties. It offers high gloss and excellent transparency, ensuring clear visibility of the contents.

![[Newly Developed Product] Easy-Open Anti-Fog CPP Film DIFAREN® S1720T](../images/products/24_prdct_04.jpg)