RePOS®

Turn “waste” into “value.”

Recycle polystyrene.

What is RePOS®?

RePOS® is a fully circular recycling model that enables used polystyrene products to be reused across a wide range of applications.

Do you face these challenges?

- Conventional recycling turns the material black and limits reuse options.

- Recycling often depends on incineration, leaving few reuse pathways.

- When asked about safety, there is little data or proven performance.

DIC’s Fully Circular Polystyrene Recycling Model: RePOS®

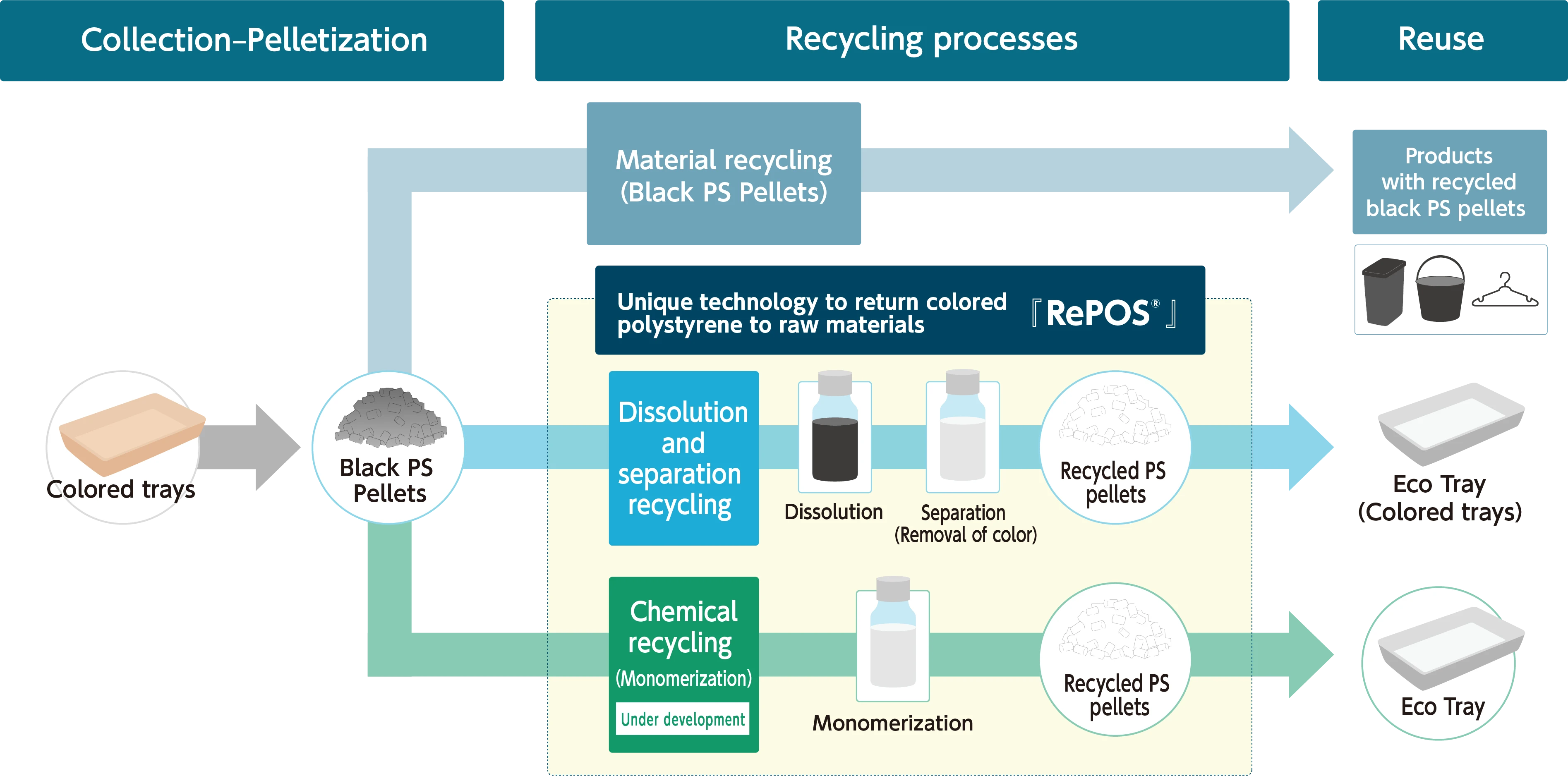

A key challenge in plastic recycling is how to reintegrate colored waste plastics into the recycling loop.

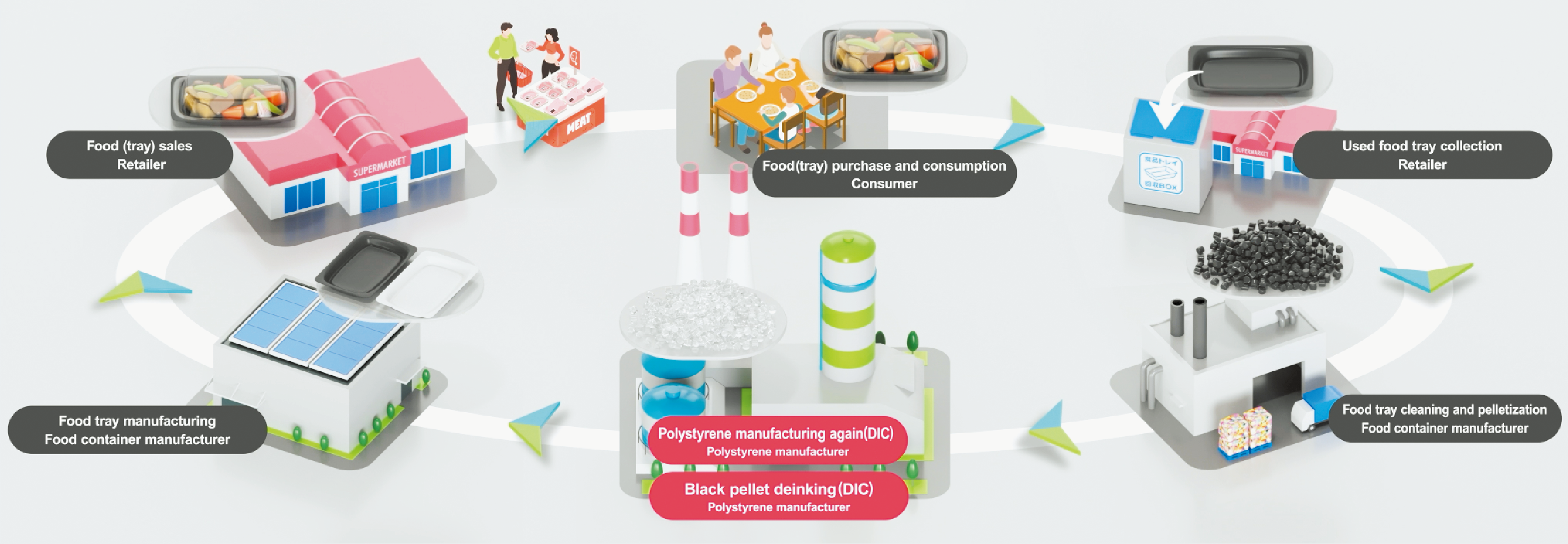

DIC is working to realize a fully circular polystyrene (PS) recycling model using both the world’s first dissolution-separation recycling technology and chemical recycling. This approach aims to enable the recycling of polystyrene—the material used in everyday food trays.

We call the products created through this fully circular polystyrene model “RePOS®.”

Dissolution-Separation Recycling(Dic Method: Deinking Chemical Process)

Used white foam trays collected from households can be recycled back into food trays; however, printed and colored trays turn into black recycled pellets during the process, limiting reuse to items such as hangers and other daily goods.

To address this, DIC leveraged its expertise in printing inks and resin design to develop the Dic Method—a new dissolution-separation technology that removes colorants from black recycled pellets, enabling them to be reused as feedstock for polystyrene production.

With the Dic Method, printed and colored foam trays can now be recycled just like white trays.

Recycling used polystyrene products back into new polystyrene products【RePOS®】

With audio (01:36)

The Current State of Plastic Recycling

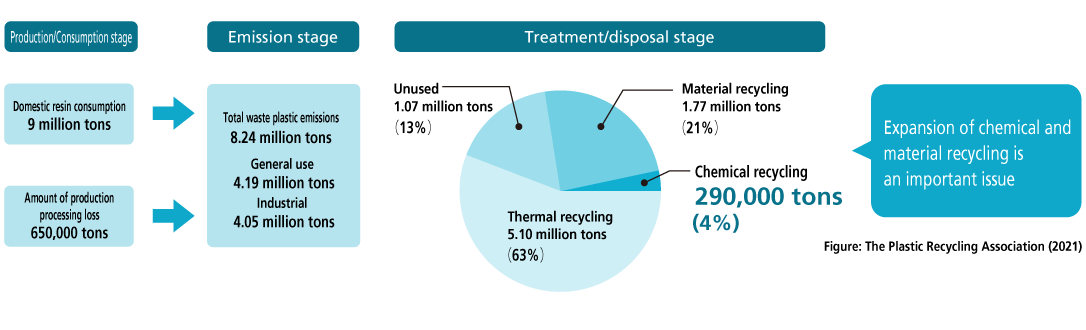

Thermal recycling is the predominant method for plastic recycling in Japan.

To realize the advanced circular society the world aims for, it is said that the widespread adoption of material recycling and chemical recycling is essential.

What DIC is pursuing through RePOS®

Partnership Agreement with Yokkaichi City, Mie Prefecture

We have signed a comprehensive partnership agreement with Yokkaichi City in Mie Prefecture to jointly advance a decarbonized society and sustainable industrial development.The agreement outlines collaborative efforts in decarbonization, resource circulation, environmental education, industrial development, and regional economic initiatives through mutual information sharing and joint programs.

In 2023, a collection box for polystyrene food containers was installed at Yokkaichi City Hall, and joint demonstration trials were conducted to assess types, quantities, and quality of collected materials.

The collection box was later moved to the environmental education classroom at the Yokkaichi Plant, where it is used for environmental learning and children’s seminars conducted in collaboration with local companies—expanding community engagement in recycling.

Recycling bins for food trays and similar items installed at the Yokkaichi Plant

We are seeking partners who share our commitment to this initiative.