Next-generation adhesive contributing for food-safe and environmentally friendly

based on ULM technology

About ULM (Next-generation adhesive)

- ・Consolidate our sustainability initiatives + contribute to food-safe with ULM technology

・Utilized as a raw material for polyurethane

・The technology is also incorporated in the new DUALAM™,

expanding the product range = contributing for CO2 reduction and food-safe in the markety

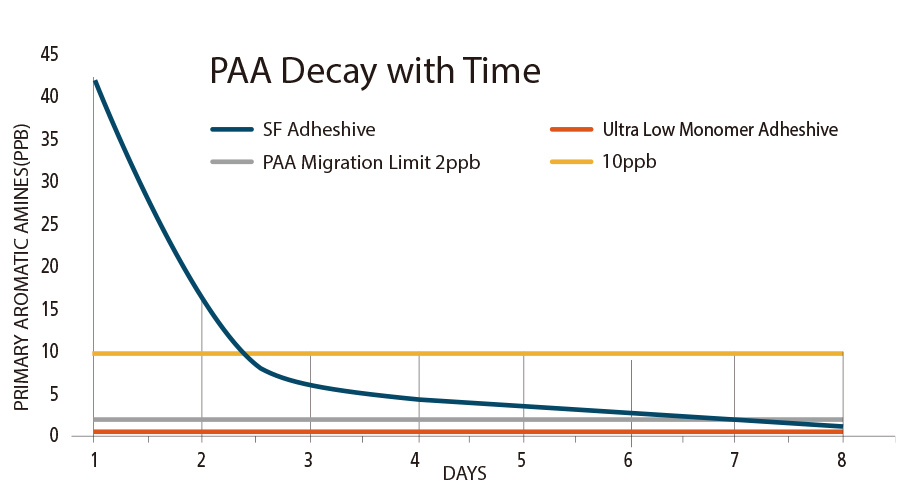

DIC has acquired 'Ultra Low Monomer' (ULM) technology, which enables the refining of urethane raw materials and the production of related products that are food-safe and environmentally friendly. By using ULM as the main raw materials, it enables the production of urethane raw materials with maximum reduction of hazardous substances and the development of sustainable adhesives.

Strengthen sales of food safety and environmentally friendly products

ULM technology complies with European regulations on isocyanate usage and reduce monomer residue to almost zero.

Promote the development of solvent-free adhesives and strengthen the product lineup

The development range of solvent-free adhesives, based on ULM technology, will be expanded with the aim of strengthening the product lineup.

Further development of the newly developed DUALAM™

Solvent-free laminating adhesives and DUALAM™

will propose to customers the elimination of solvents and the reduction of CO2 emissions during processing.