Hands-On Safety Training Facilities Established at DIC Group Companies in Thailand and India —Part of a Global Effort to Cultivate Greater Awareness of Safety—

- Sustainability

- News Release

Tokyo, Japan–DIC Corporation today announced that two overseas DIC Group companies, in Thailand and India, have established facilities for hands-on safety training, which simulates latent risks in the workplace, including on production floors, such as being caught in machinery, tumbling and falling from a high place.

Facilities were established by Siam Chemical Industry Co., Ltd., which manufactures and sells synthetic resins, at its plant in Samut Prakan province, and by DIC India Ltd., which manufactures and sells printing inks, at its Noida plant. Both companies began providing hands-on safety training for Group employees in their respective countries in August 2017.

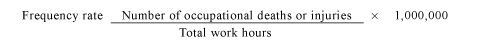

Hands-on safety training uses actual equipment to simulate accidents in the workplace, thereby heightening awareness of the importance of proper safety. In Japan, DIC initiated a full-fledged hands-on safety training program in 2012 with the introduction of a mobile initiative centered on a 10-tonne truck that travels from site to site. Since 2013, the Company has promoted the horizontal deployment of these efforts across the global DIC Group by, among others, establishing six permanent facilities in Japan, three in Greater China and Taiwan, Malaysia, Indonesia. Underscoring the success of these efforts, DIC has halved its occupational accident frequency rate* in Japan from the level prior to introducing hands-on safety training.

The DIC Group’s hands-on safety training simulates common workplace accidents—including those involving entanglement in rotating devices, falls from high places and incised wounds caused by cutting equipment—based on actual previous examples with the aim of reducing employees’ willingness to accept risks and fostering their ability to recognize danger. In doing so, DIC seeks to transform the mindset of employees by encouraging them to think and act on their own to protect themselves and each another from latent risks. To date, more than 10,000 Group employees have participated in hands-on safety training.

As part of a larger effort to cultivate awareness of safety, DIC first began providing hands-on safety training overseas under guidance—including the establishment of facilities in Greater China, Malaysia and Indonesia—from Japan. The Company also provides education to qualify Group company environment, health and safety (ESH) officers as hands-on safety instructors to oversee the training for local employees, underpinning a steady increase in awareness of safety at DIC Group companies worldwide. The establishment of facilities at Siam Chemical Industry and DIC India marks the first time first time local Group companies and employees have spearheaded such a move.

Looking ahead, the DIC Group will continue working to maximize local hands-on safety training facilities, as well as to step up safety initiatives with the goal of increasing awareness of safety in line with its stated objective of achieving zero occupational accidents.

-Ends-

PDF download

*Note: The files are in Adobe Acrobat Format. To view them you will need Acrobat Reader.