UV-reactive Surface Modifiers

MEGAFACE RS Series

Functional Products

Electronics

Automotive

Packaging

Health Care

Color

Display

House Equipment / Infrastructure

Functional Materials

MEGAFACE RS Series

Functional Products

Electronics

Automotive

Packaging

Health Care

Color

Display

House Equipment / Infrastructure

Functional Materials

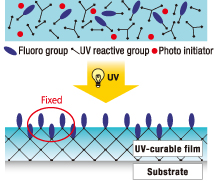

MEGAFACE RS Series is a surface modifier developed by DIC's unique additive design techniques. Adding RS Series to UV coating provides functions to repel water and oil well and to prevent the adherence of fingerprints or stains to a coating film surface.

Since it possesses UV-reactive groups, it has excellent durability because fluorine components are secured to the surface of the coating. It can be used to protect the surface of optical films and the bodies of electronic devices.

Exhibits an effect that repels oil-based pens and fingerprints

The coating will have excellent fingerprint resistance ie prevention of fingerprint markings and also easy cleaning property.

Stain-guard performance improves by UV curing under nitrogen atomosphere.

Can be effectively used for partitions between display pixels because it repels oil only on the top surface when UV-curable.

Capable of adding chemical resistance including alkali resistance to the coating surface. It can also be used effectively for negative resist such as color resists because it can add chemical resistance to only the UV exposed sections.

RS-75, which shows excellent performance in protecting the surface of optical films and electronic device bodies, and RS-72-K, a PGMEA solution suitable for resist applications.

MEGAFACE RS-75: Active components 40% (Solvent: MEK/MIBK=93/7)

MEGAFACE RS-72-K: Active components 30% (Solvent: PGMEA)

MEGAFACE RS-76-E: Active components 40% (Solvent: MEK/Ethyl acetate/MIBK=76/22/2)

MEGAFACE RS-76-NS: Active components 20% (No Solvent - Diluted with DPGDA)

MEGAFACE RS-78: Active components 40% (Solvent: MIBK)

MEGAFACE RS-90: Active components 10% (Solvent: HFX/MEK=74/26)

MEGAFACE RS-55: Active components 40% (Solvent: MIBK)

MEGAFACE RS-56: Active components 40% (Solvent: MIBK)

| Application examples | Recommended product numbers | Surface characteristics |

|---|---|---|

| Optical films (LCD, touchscreens), cellular telephones (screen, body) | RS-75, RS-76-E, RS-76-NS, RS-90, RS-78, RS-55, RS-56 | Stain resistance, slipperiness |

| Partitions (LCD black matrix, organic EL) | RS-72-K | Ink repellency |

| Color resist (LCD color filters) | RS-72-K | Film thinning prevention |

| Additives | MEGAFACE RS-75 | No additives | ||

|---|---|---|---|---|

| Additive amount | 1.0 wt% | |||

| Color of marker | Blue | Black | Blue | Black |

| UV-cured under nitrogen | Marker is repelled |  |

|

|

|

|

|||

| UV-cured under air |  |

|

|

|

| Additives | MEGAFACE RS-75 | No additives |

|---|---|---|

| Additive amount | 1.0 wt% | |

| Immediately after fingerprints are left [magnified] (UV cured under nitrogen) |

Fingerprints are repelled |

Fingerprints stained the surface |

| After wiping off the fingerprints [magnified] (UV cured under nitrogen) |

Fingerprints are completely cleaned |

Traces of fingerprints remain |