With Suppliers

Goals and Achievements of Major Initiatives

Promote sustainable procurement.

| Goals for fiscal year 2022 | Promote initiatives aimed at expanding the use of sustainable raw materials over the medium to long term (calculate the carbon footprint of raw materials and continue to search for bioderived and recycled raw materials). |

|---|---|

| Achievements in fiscal year 2022 |

|

| Evaluation | ★★ |

| Goals for fiscal year 2023 | Advance initiatives aimed at expanding sustainable procurement over the medium to long term, including assessing and reducing CO₂ emissions associated with raw materials and searching for bioderived and recycled raw materials. |

| Goals for fiscal year 2022 | Continue conducting assessments to better ascertain the sustainability of DIC and Sun Chemical suppliers and ensure a grasp of their overall ESG initiatives. |

|---|---|

| Achievements in fiscal year 2022 | DIC completed assessments of suppliers accounting for more than 80% of its procurement spending in Japan. Sun Chemical completed assessments of suppliers accounting for approximately 71% of its procurement spending. |

| Evaluation | ★★ |

| Goals for fiscal year 2023 | Continue conducting sustainability assessments of suppliers in Japan and Sun Chemical suppliers, and expand the scope of this initiative to include the PRC and the Asia– Pacific region, to ensure a grasp of, and encourage improvement of, suppliers’ sustainability initiatives. |

- Evaluations are based on self-evaluations of current progress.

Key: ★★★ = Excellent; ★★ = Satisfactory; ★ = Still needs work

Basic Approach to Sustainable Procurement

Having recognized the increasing importance of addressing issues essential to sustainable procurement, including compliance with laws and social norms, consideration for the environment and respect for human rights, the DIC Group formulated the DIC Group Universal Purchasing Policy and continues to advance related initiatives on a global scale. Based on this policy, the Group also established the DIC Group Sustainable Procurement Guidelines, which clarifies its expectations of suppliers, and advances sustainable procurement across its supply chains by ensuring assessments are conducted to ascertain the status of suppliers’ sustainability and by encouraging awareness-raising efforts.

For more information, please visit https://www.dic-global.com/en/csr/stakeholder/partner.html

The DIC Group Universal Purchasing Policy

Guided by an action policy established to realize the DIC Group’s basic sustainable procurement principles, the Purchasing Department adheres to the following guidelines in dealing with suppliers:

- Fair and transparent business practices

The DIC Group will implement fair and open purchasing activities with suppliers based on global perspectives, without the constraints of conventional commercial customs. - An appropriate purchasing process and the building of relationships of mutual trust

The DIC Group, as a good partner for suppliers, will build long-lasting, mutually trusted relationships with suppliers and work together with them for mutual harmony and benefit, while complying with relevant regulations/social norms, domestic and overseas, and pursuing adequate quality and prices. - Satisfying environmental/safety needs

The DIC Group will take responsibility as an exemplary corporate citizen for environmental affairs, occupational safety, human health and product quality, always take into account changes in society and implement environment-friendly purchasing activities. - Challenge the creation of new value

In order to respond at a high level to a new value sought by society, the DIC Group will proactively challenge the creation of such value together with suppliers, with whom the same goal can be shared, and strive to grow together with them in a sustainable manner.

The DIC Group Sustainable Procurement Guidelines

- Compliance with laws/social norms

- Human rights and work environments

- Safety and health

- Consideration for the environment

- Information security

- Appropriate quality and safety and technological improvements

- Stable supplies and flexible responses to change

- Promotion of sustainability and sustainable procurement initiatives

Ascertaining and Improving Suppliers’ Sustainability

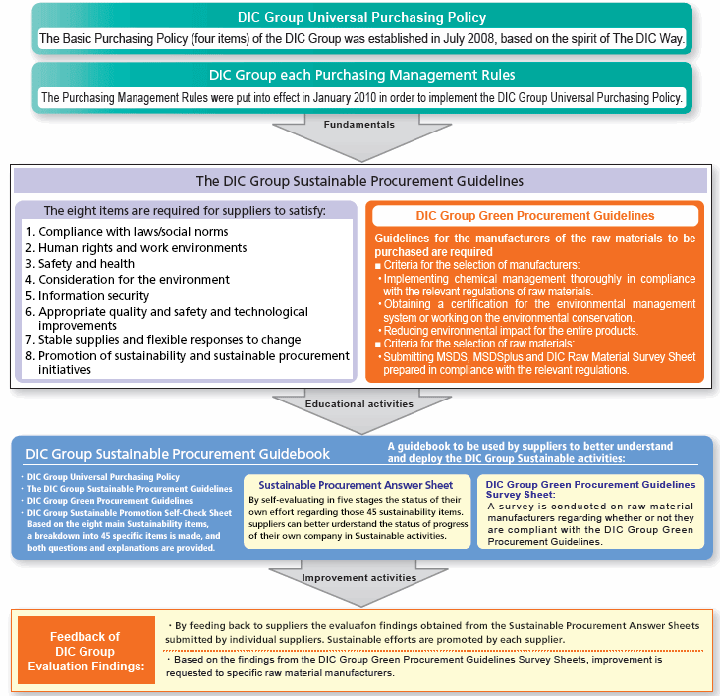

The DIC Group uses the DIC Group Sustainable Procurement Guidebook and the EcoVadis* platform to assess the status of its suppliers’ sustainability initiatives.

- The web-based sustainability rating platform provided by EcoVadis SAS assesses the performance of companies, providing sustainability scorecards and benchmarks, and has been used to evaluate more than 100,000 companies worldwide.

Global Sustainable Procurement Efforts

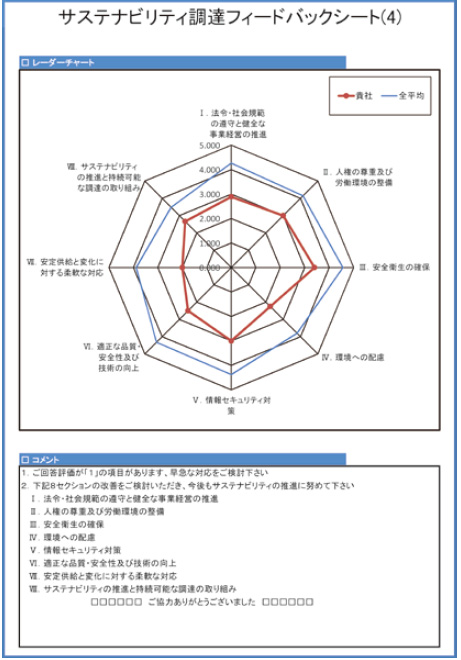

In Japan, the DIC Group Sustainable Procurement Guidebook is used to assess suppliers’ sustainability and promote improvements. In addition to encouraging awareness of its expectations of suppliers, outlined in the DIC Group Sustainable Procurement Guidelines, which are included in the guidebook, the DIC Group conducts surveys using the guidebook’s self-evaluation sheet to ascertain the status of suppliers’ sustainability initiatives. The self-evaluation sheet consists of 45 questions segmented into the same eight categories as the DIC Group Sustainable Procurement Guidelines.

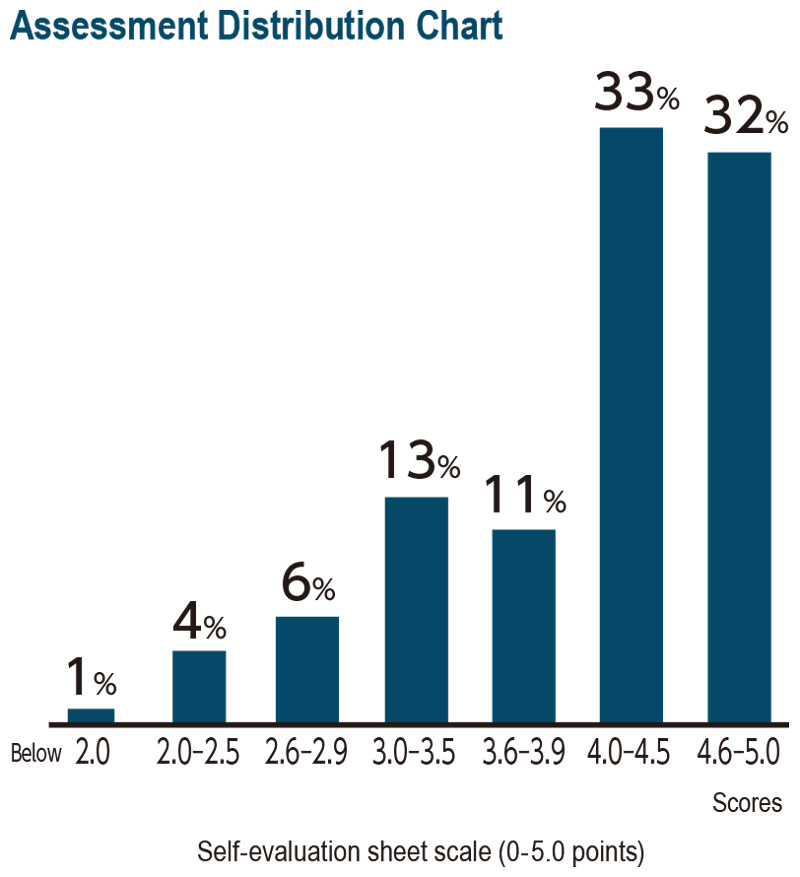

In fiscal year 2022, the DIC Group completed assessments of suppliers accounting for more than 80% of its procurement spending in Japan using version 3 of the DIC Group Sustainable Procurement Guidebook. In addition to analyzing and assessing responses to self-evaluation sheet questions and providing feedback to each supplier, the Group follows up with on-site inquiries or written comments for suppliers whose initiatives were found to be insufficient. On-site inquiries were suspended from fiscal year 2020 through fiscal year 2022 because of COVID-19, but the Group intends to resume on-site inquiries gradually from fiscal year 2023, as well as to begin also conducting inquiries online. The Group will also expand the scope of assessments conducted using the DIC Group Sustainable Procurement Guidebook beyond Japan to suppliers in the PRC and the Asia–Pacific region.

Additionally, the DIC Group in Japan uses the DIC Group Green Procurement Guidelines, also contained in the DIC Group Sustainable Procurement Guidebook, to oblige suppliers to ensure the stringent management of chemical substances and compliance with pertinent laws and regulations, as well as to promote the reduction of environmental impact. Using the appropriate survey form, the Group also confirms suppliers’ own green procurement efforts, ascertains the status of manufacturers’ responses to requests for improvements and follows up as necessary.

In the Americas and Europe, Sun Chemical continues to assess the sustainability of suppliers using EcoVadis rather than the DIC Group Sustainable Procurement Guidebook. In fiscal year 2022, the company completed assessments of suppliers accounting for approximately 60%* of its procurement spending.

Responsible Procurement of Minerals

The DIC Group has formulated Basic Approach to the Responsible Procurement of Minerals, recognizing the importance of procuring these critical resources in a responsible manner and engaging with suppliers to address this challenge across its supply chains.

Basic Approach to the Responsible Procurement of Minerals

To avoid any complicity in the funding of armed groups, or in child labor or other human rights abuses, in areas of conflict—including the Democratic Republic of Congo and its neighboring countries—or high-risk areas,* the DIC Group surveys suppliers of minerals such as tin, tantalum, tungsten and gold to ensure the responsible procurement thereof across its entire supply chain. Should it discover the use of minerals mined in conditions of conflict or as a result of human rights abuses, the Group will take immediate corrective actions.

In line with this approach, the DIC Group uses the conflict minerals reporting template (CMRT) and the extended minerals reporting template (EMRT)* for minerals contained in procured raw materials. To date, surveys using the CMRT have been secured regarding more than 90% of the raw materials the Group currently procures in Japan. Surveys using the EMRT have also been conducted for major raw materials containing target minerals. The Group will continue to expand and update its surveys in the future.

- The CMRT and EMRT are standardized reporting templates developed by the Responsible Minerals Initiative (RMI) to survey smelters and refineries used for minerals contained in raw materials, with the CMRT targeting tin, tantalum, tungsten and gold and the EMRT targeting mica and cobalt. This facilitates the transfer of information on minerals across entire supply chains.

Advance Assessment of New Suppliers

The DIC Group conducts advance assessments of new raw materials to confirm that there are no issues regarding legal or regulatory compliance, safety or other issues related to the sustainable procurement of raw materials. In Japan, for example, the Group mandates the submission of a DIC Raw Materials Survey,*1 a safety data sheet (SDS), a chemSHERPA*2 and a CMRT.

- A DIC Raw Materials Survey is a questionnaire the aim of which is to confirm basic information on the constituents of raw materials and their compliance with pertinent laws and regulations.

- An acronym for “chemical information sharing and exchange under reporting partnership in supply chain,” chemSHERPA is a scheme developed in Japan for the transfer of information on raw materials throughout supply chains.

Ensuring the Sustainable Procurement and Use of Raw Materials

Surveys of CO₂ Emissions Associated with Raw Materials

In response to social imperatives and the expectations of its customers, in fiscal year 2022 the DIC Group began surveying CO₂ emissions associated with raw materials, to calculate the carbon footprint of its products, that is, total CO₂ emitted over its products’ life cycles. The Group will continue to conduct these surveys to collect relevant data, enabling it to accurately calculate and take steps to reduce its products’ carbon footprint.

Supplier Engagement

In response to social imperatives and the expectations of its customers, in fiscal year 2022 the DIC Group began surveying CO₂ emissions associated with raw materials, to calculate the carbon footprint of its products, that is, total CO₂ emitted over its products’ life cycles. The Group will continue to conduct these surveys to collect relevant data, enabling it to accurately calculate and take steps to reduce its products’ carbon footprint.

- For more information on the SBTi, please see page 86.

Promoting the Use of Bioderived and Recycled Raw Materials

The DIC Group actively promotes the use of bioderived and recycled raw materials. This includes using the Group’s global supply chain to conduct raw material surveys and sharing the results with technical groups, prompting product design reviews.

COMMENT

Sojitz and DIC are working together to promote sustainable development.

Sojitz Corporation has supplied DIC with raw materials for resins for some time. We have established Sustainability Challenge, a long-term sustainability vision that will guide our efforts until 2050, and declared our commitment to contributing to the realization of a decarbonized society and expanding step-by-step initiatives to respect human rights, including within our supply chains. Improving respect for human rights in one’s own supply chains requires the understanding and cooperation of our business partners, so DIC, which has been working to do just that since 2008, is an encouraging presence. While an increasing number of companies have established sustainable procurement guidebooks and are conducting supply chain inquiries on an ongoing basis, not many go so far as to provide feedback to their business partners. With social imperatives that impact companies’ entire supply chain expected to continue gathering steam, we look forward to collaborating further with DIC to create shared value and promote sustainable development.

Specialty Chemicals Department, Sect. 3, Chemicals Division, Sojitz Corporation Di Liu

VOICE

We are working to build partnerships with suppliers through sustainable procurement.

In addition to manufacturing and selling inks, DIC Graphics provides solutions that encompass the proposal and sale of products sourced from other manufacturers. My department is in charge of procuring such products, which are diverse in nature and include solvents used in inks, printing plates and chemical cleaning agents used on printing floors, as well as equipment that helps customers reduce labor requirements. We currently work with approximately 300 suppliers. Sustainable procurement initiatives are essential to building effective partnerships with these companies. Supplier inquiries have traditionally focused on considerations such as quality, price and stable supply capabilities, but we recognize the increasing importance of sustainable procurement, which incorporates ESG perspectives, to our efforts to finding and building partnerships with promising suppliers.

Manager, Raw Materials Management, Supply Chain Management Group, DIC Graphics Corporation

Kazunori Karasawa

We promote sustainable procurement by implementing continuous improvement.

I work for at DIC Synthetic Resins (Zhongshan), where I am in charge of procuring raw materials for metal carboxylates used in tires. The supply chain for these metal carboxylates depends on leading global brand owners and supplies of raw materials from a limited number of suppliers. Accordingly, we view each supplier as an indispensable business partner and work to build relationships based on mutual trust while striving to ensure sustainable procurement. To improve quality and promote sustainability across the supply chain, we regularly survey suppliers using questionnaires, while purchasing, quality assurance and production staff conduct audits to deepen mutual understanding of the status of efforts to comply with laws and regulations, ensure occupational safety and health, and protect the environment. We provide feedback to suppliers on audit results and request corrective actions when standards are not met while at the same time providing related information to support improvements. As part of our efforts to ensure responsible procurement of minerals, we collaborate with corporate headquarters to conduct surveys of companies supplying processed cobalt products jointly and share information. In August 2019, DIC Synthetic Resins (Zhongshan) was awarded a silver medal by EcoVadis for its ESG initiatives. Rather than being satisfied with where we are now, however, I look forward to working actively with suppliers to further advance the sustainability of our procurement practices.

Officer, Procurement Department, DIC Synthetic Resins (Zhongshan) Co., Ltd.

Yu Fang Zhou

Related Link