New CFRP Prepreg Sheet

DICARBO® LF

New Business / Developed Products

Electronics

Automotive

House Equipment / Infrastructure

Functional Materials

DICARBO® LF

New Business / Developed Products

Electronics

Automotive

House Equipment / Infrastructure

Functional Materials

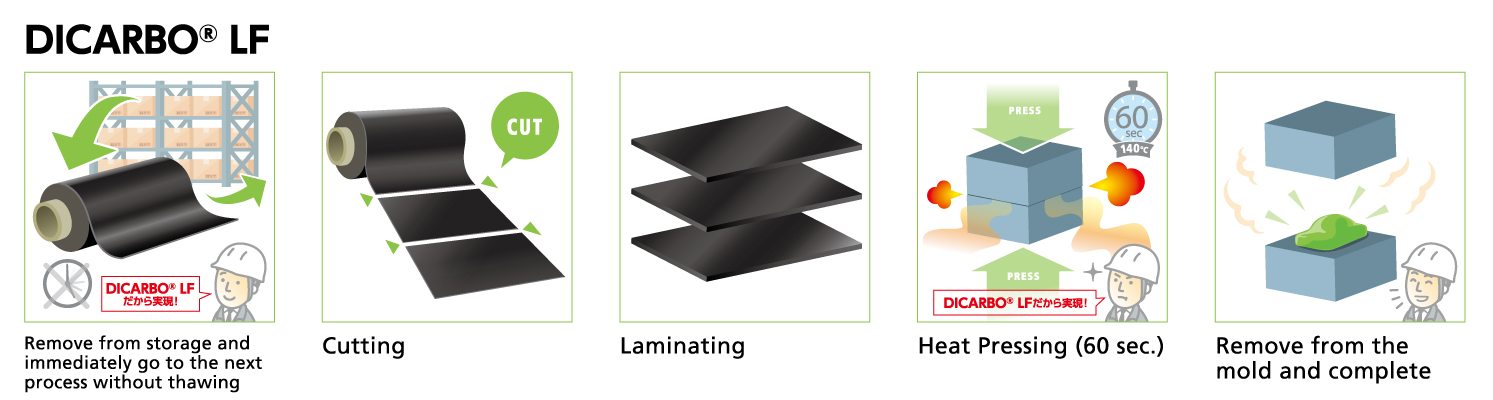

*Sheet like intermediate material made by spreading and arranging carbon fiber bundles and soaking them with resin

| Properties | Unit | Standard type | Low-temperature type | |

|---|---|---|---|---|

| Matrix resin | Radiation curable resin | Radiation curable resin | ||

| Fiber Type | Unidirectional | Unidirectional | ||

| Carbon fiber weight | g/㎡ | 100 | 100 | |

| Resin content | Wt% | 34 | 34 | |

| Prepreg weight | g/㎡ | 150 | 150 | |

| Thickness | μm | 100 | 100 | |

| Storage conditions | 23℃ 6 months | 23℃ 3 months | ||

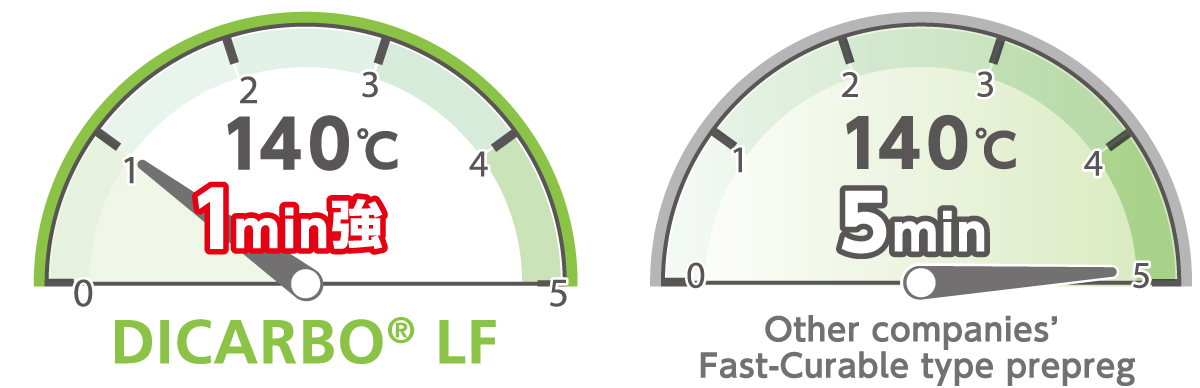

| (Ex)Mold temperature | ℃ | 140 | 100 | |

| (Ex)Deforming time | minutes | 1 | 5 | |