Acrylic Sol Plasticizers

W-23-S, PB-10

Functional Products

Electronics

Automotive

Packaging

Health Care

Color

Display

House Equipment / Infrastructure

Functional Materials

W-23-S, PB-10

Functional Products

Electronics

Automotive

Packaging

Health Care

Color

Display

House Equipment / Infrastructure

Functional Materials

Acrylic sol plasticizers Polycizer W-23-S and Monocizer PB-10 excel in storage stability and have the effect of accelerating gelling and melting. They also possess capabilities to improve interfacial fusion between primary particles.

Good compatibility with core shell acrylic resins, excellent storage stability (sol stability), and superior properties after melting and gelling.

Good acrylic sol gelling compared to DINP

W-23S has good elongation and tensile strength compared to DINP

PB-10 has extremely good elongation compared to DINP

Good compatibility after melting and gelling

Automobile undercoats, chipping coatings, sealings

Textile inks for T-shirts

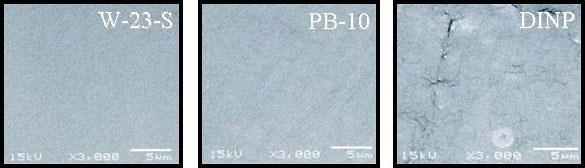

Comparing the fracture cross section of molded products with DINP, DIC's modifier has a smooth surface and good interfacial fusion between primary particles.

<Composition>

Acrylic powder 100

Plasticizer 100

130°C x 30 minutes