Special Feature Our Efforts in Environmental Responsiveness with Printing Ink Products

In the midst of environmental protection activities expanding worldwide, the printing ink industry is no exception. Ink products not using hazardous substances (soy-oil ink and vegetable ink) of which decrease the use of petroleum-derived solvents have been developed. Even "none-VOC ink," which does not contain any petroleum-derived solvents, is gaining momentum in its market share. Waterless printing ink, which does not discharge water, can contribute to a reduction in VOC release from the entire printing process. We are also prepared to supply a special kind of ink, suitable for LED-UV lighting which is used at the drying stage to reduce electricity consumption, and another kind of ink with the property of easiness in recycling, etc. Thus, we have various kinds of products compliant with environmental protection activities through printing. It is possible to select an environment-conscious printing ink of best choice, depending on the customer's needs.

Offset Ink for LED-UV

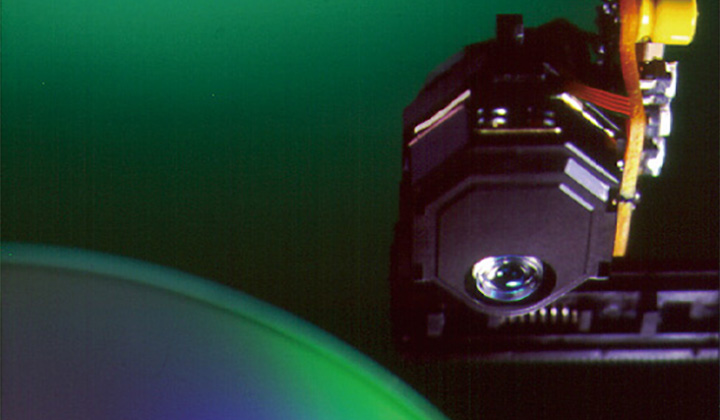

The UV ink is designed to cure instantaneously through a photochemical reaction by means of UV energy, thereby showing a higher productivity than oil-based ink with natural drying characteristics, and this ink is also of the environment-conscious type (no VOC is contained). Due to these characteristics, the printing utilizing the UV ink has been broadly employed mainly for package printing for which many processing stages are required and therefore rigorous physical properties come into play. Recently, the high productivity and highly value-added property of the UV printing are drawing attention also in the field of general printing.

When using the LED-UV printing system, a reduction of 70 to 80% of electricity consumption can be expected as compared with the printing system using a conventional UV lamp. Also, partial lighting can be adopted easily, accommodating different paper sizes. So, these characteristics contribute to a reduction in environmental impact. Furthermore, there are various advantages: the lamp serves for a prolonged period of time, more than 10 times longer than before; improved productivity can be expected since the on/off operation is simple to do; there is no formation of ozone; and no thermal deformation occurs in printed matters. On the other hand, since the LED-UV lamp is weak in irradiation intensity and its light contains no short-wave UV light, sufficient curing is hardly attained for conventional ink. To cope with this problem, Daicure ABILIO® LED offers a UV offset ink, which cures under an LED-UV lamp without allowing its excellent ink properties to change.

Process Ink for Sheet-fed Printing

Having the world's top share* in printing ink and organic pigments, DIC Group is promoting the optimization of the ink production/supply system globally. We started the production of environment-conscious sheet-fed process ink, called SunLitTM Diamond, at a global mother plant newly established at the Dahej special economic zone in Gujarat Province in eastern India, from the end of last year. So, we are promoting the global supply from there.

The aforementioned plant is a state-of-the-art automated plant with its core equipment from Europe and is capable of producing high-quality sheet-fed process ink efficiently. We plan to expand its capacity in stages from now on, and bring it to a plant with a huge capacity, 30,000 tons per year, at the final stage.

The sheet-fed process ink supplied from this plant to various places globally, contributes to carbon offset as a non-VOC product, also environment-conscious in compliance with international standards, such as RoHS, REACH and EN71/3. As a global mother plant, this is the second one following the Nantong plant, established in China. In the DIC Group, we will continue to work on the optimization of the production/supply of various kinds of ink.

- As for our global share, the printing ink shares approximately 30% and organic pigments share approximately 25%. The organic pigments are the main raw materials for the printing ink.

Special Topics before 2012

The DIC Group:Striving for a Sustainable Society Utilizing the Power of Chemistry to Solve Problems and Create New Value

Shipping, information, housing, food products—there are number of problems that need solving in the industrial fields that support our daily lifestyles. Through creative development of new products, the DIC Group is contributing to solutions for such problems while generating new value.

Placing top priority on safety, the environment and health while maximizing benefits from chemical products

While supporting customer lifestyles through our wide variety of chemical products, the DIC Group makes efforts to ensure safety, protect the environment and ensure health in every phase of the product life-cycle.

Our Efforts in Environmental Responsiveness with Printing Ink Products

Ink products not using hazardous substances (soy-oil ink and vegetable ink) of which decrease the use of petroleum-derived solvents have been developed.

Urethane Resin for Artificial Leather

In order to respond to the requirement for the decreasing of VOC inside the vehicle, we are also putting our efforts into the development of environmentally friendly products, such as toluene-free and water-based materials.

Halogen-free PPS Resin

DIC has successfully decreased the chlorine content of the PPS resin to a level lower than the requirement level, 900 ppm. Thus, DIC has completed the lineup of low-halogen PPS compounds.

Environment-conscious Adhesives Used for Food Packaging

DIC has developed various types of adhesives to prevent the release of VOC such as a high-solid type in which the amount of organic solvent is reduced, a water-based type for which tap water can be used.